Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of construction and industrial projects, choosing the right materials is paramount to ensure safety, durability, and efficiency. One such material that has garnered attention for its superior qualities is the 3 8 Coated Cable. This type of cable, distinguished by its protective coating, provides numerous benefits that enhance its performance in various applications. Whether it's for electrical installations, structural supports, or outdoor setups, understanding the advantages of 3 8 Coated Cable can significantly impact the success of any project.

The protective coating on 3 8 Coated Cable not only offers resistance to environmental factors such as moisture and corrosion but also enhances its mechanical strength and durability. This makes it an ideal choice for demanding environments where traditional cables might falter. Furthermore, the flexibility and ease of handling associated with 3 8 Coated Cable allow for seamless integration into a wide range of applications, from construction to outdoor events. By delving into the various applications and benefits of this versatile cable, project managers and engineers can make informed decisions that lead to safer and more reliable project outcomes.

3/8 coated cable is gaining recognition in various industries due to its unique composition and impressive characteristics. This type of cable typically features a steel wire core coated with a durable layer of polymer, which enhances its performance and longevity. The steel core provides the necessary strength for heavy-duty applications, while the coating offers resistance to environmental factors such as moisture, UV rays, and abrasion. According to industry reports, cables with coatings can improve lifespan by up to 30%, making them a cost-effective choice for long-term projects.

One notable characteristic of 3/8 coated cable is its flexibility, which allows for easier handling and installation. Unlike traditional uncoated cables, the coating enables the cable to maintain its integrity even during tight bends. This feature is particularly valuable in construction and rigging, where maneuverability is essential. Additionally, the chemical resistance of the coating makes it suitable for use in various environments, including industrial settings where exposure to harsh substances is common.

Tips: When selecting 3/8 coated cable for your projects, consider the specific environmental factors it will encounter, such as temperature variations and exposure to chemicals. Understanding these elements can guide you in choosing the right type of cable for optimal performance. Moreover, always ensure that the cable meets industry standards for safety and efficacy—this will help mitigate risks and enhance the reliability of your installations.

3/8 coated cable has become an essential component in various construction projects, offering numerous advantages that enhance both safety and efficiency. One of the primary benefits of this type of cable is its superior resistance to environmental factors. The coating provides protection against moisture, UV rays, and other elements that can lead to corrosion or degradation over time. This durability ensures that the cable maintains its integrity, reducing the need for frequent replacements and ultimately saving on maintenance costs.

Another significant advantage of 3/8 coated cable lies in its versatility. It can be used in a multitude of applications, from heavy lifting in construction sites to securing structures and equipment. Its strength and reliable performance make it ideal for both temporary and permanent installations. Additionally, the lightweight nature of the cable, combined with its strength, allows for easier handling and installation, which can expedite project timelines. This efficiency is crucial in the construction industry, where time and resource management are vital for project success.

Moreover, the use of 3/8 coated cable enhances safety on the job site. The outer coating not only provides a non-slip surface but also helps to visually distinguish the cable, reducing the risk of accidents. Workers can easily identify and handle the cable, promoting a safer working environment. Overall, the integration of 3/8 coated cable into construction projects leads to improved operational efficiency, reduced costs, and enhanced safety standards.

3/8 coated cable has emerged as a versatile solution across multiple industries due to its unique properties. One of the most prominent applications can be found in construction, where it is used for rigging, lifting, and securing heavy loads. The cable's durability, coupled with its specialized coating, provides resistance to wear and environmental factors, making it ideal for scaffolding and other temporary structures. Additionally, its strength allows for safe and efficient handling of heavy machinery and equipment.

In the transport sector, 3/8 coated cable plays a crucial role in securing cargo during transit. Its robust design helps in minimizing load shifts, ensuring safety on the roads or railways. Furthermore, it finds application in maritime industries for mooring and towing purposes, where exposure to harsh marine conditions necessitates a cable that can withstand corrosive elements while maintaining its integrity. With the coating providing extra grip, it enhances the ease of handling during operations, thereby improving overall efficiency and safety.

Moreover, the agricultural sector benefits from 3/8 coated cable in various ways, including its use for fencing and supporting structures like greenhouses. The cable's resistance to weather conditions, alongside its strength, enables farmers to secure their assets effectively, reducing maintenance costs and enhancing productivity. Its adaptability makes it a preferred choice for many diverse applications, ensuring that it remains a pivotal component in various industries.

| Application | Industry | Benefits | Common Usage |

|---|---|---|---|

| Suspension Systems | Construction | Durability and strength, ideal for heavy loads | Hanging structures and supports |

| Cable Management | Data Centers | Organized pathways for cables, reducing clutter | Routing data and power cables |

| Marine Applications | Marine Industry | Corrosion-resistant coating, longevity in water | Anchoring and mooring systems |

| Agricultural Tools | Agriculture | Resilient to wear, effective under harsh conditions | Supporting equipment and structures |

| Art Installations | Art and Design | Aesthetic appeal, flexible in usage | Hanging and supporting artworks |

When installing 3/8 coated cable, ensuring the integrity and safety of your project is paramount. Start by preparing the surface where the cable will be installed. Clean the area of debris and dust to ensure the adhesive or mounting type adheres properly. When measuring out lengths, always add an extra few inches to accommodate any adjustments that might be necessary during installation.

Tips: Always wear protective gloves when handling coated cables to avoid cuts or abrasions. Use a cable cutter specifically designed for coated cables; this will help maintain the integrity of the coating and prevent fraying.

As you work on your project, consider using a cable spool or reel which can simplify the unwinding process. Carefully lay out the cable without kinks or twists to avoid stress points. If you need to make connections or terminate the cable, use heat-shrink tubing or suitable connectors to protect the cable ends from moisture and damage. Proper cable management and securing will prolong the lifespan of your installation.

Tips: Regularly inspect your installation for any signs of wear or damage, and address issues promptly to prevent complications in the future. Implementing these best practices will ensure your 3/8 coated cable is installed efficiently and effectively.

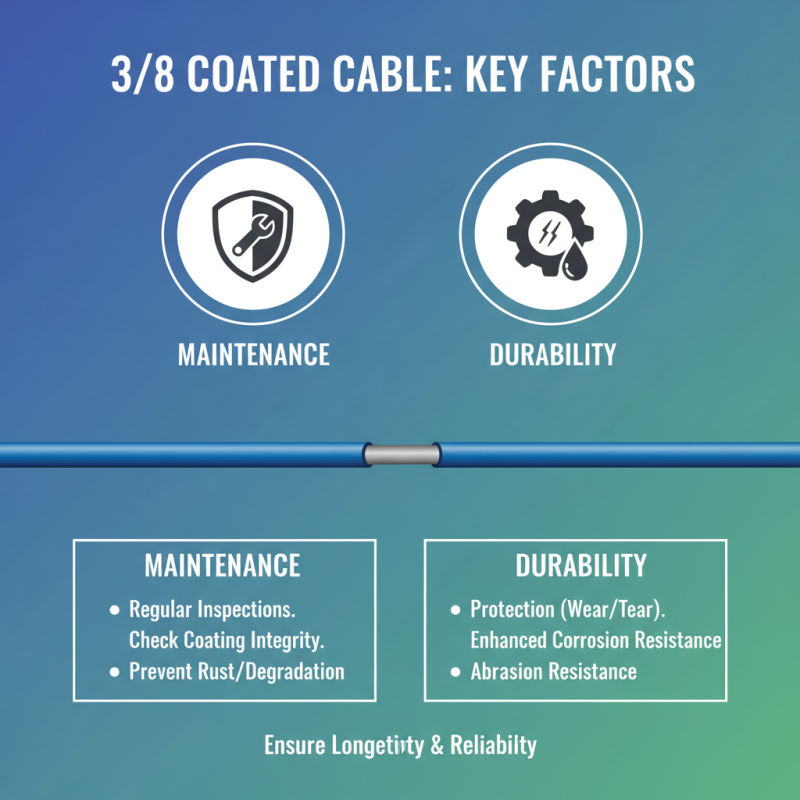

When considering the use of 3/8 coated cable for various projects, maintenance and durability are crucial factors that cannot be overlooked. The coating on this type of cable not only provides a layer of protection against environmental wear and tear but also enhances its resistance to corrosion and abrasion. Regular inspections are essential to ensure that the coating remains intact, as any damage can expose the underlying material to harsh conditions, potentially leading to rust or degradation over time.

Moreover, proper handling and storage practices play a significant role in prolonging the life of 3/8 coated cable. Avoiding sharp bends and excessive tension when installing the cable is vital to maintaining its structural integrity. Additionally, storing the cable in a dry, temperature-controlled environment can help prevent common issues such as knotting or fraying. By following these maintenance guidelines, users can maximize the longevity and reliability of their 3/8 coated cable, ensuring optimal performance throughout the intended lifespan of their projects.