Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

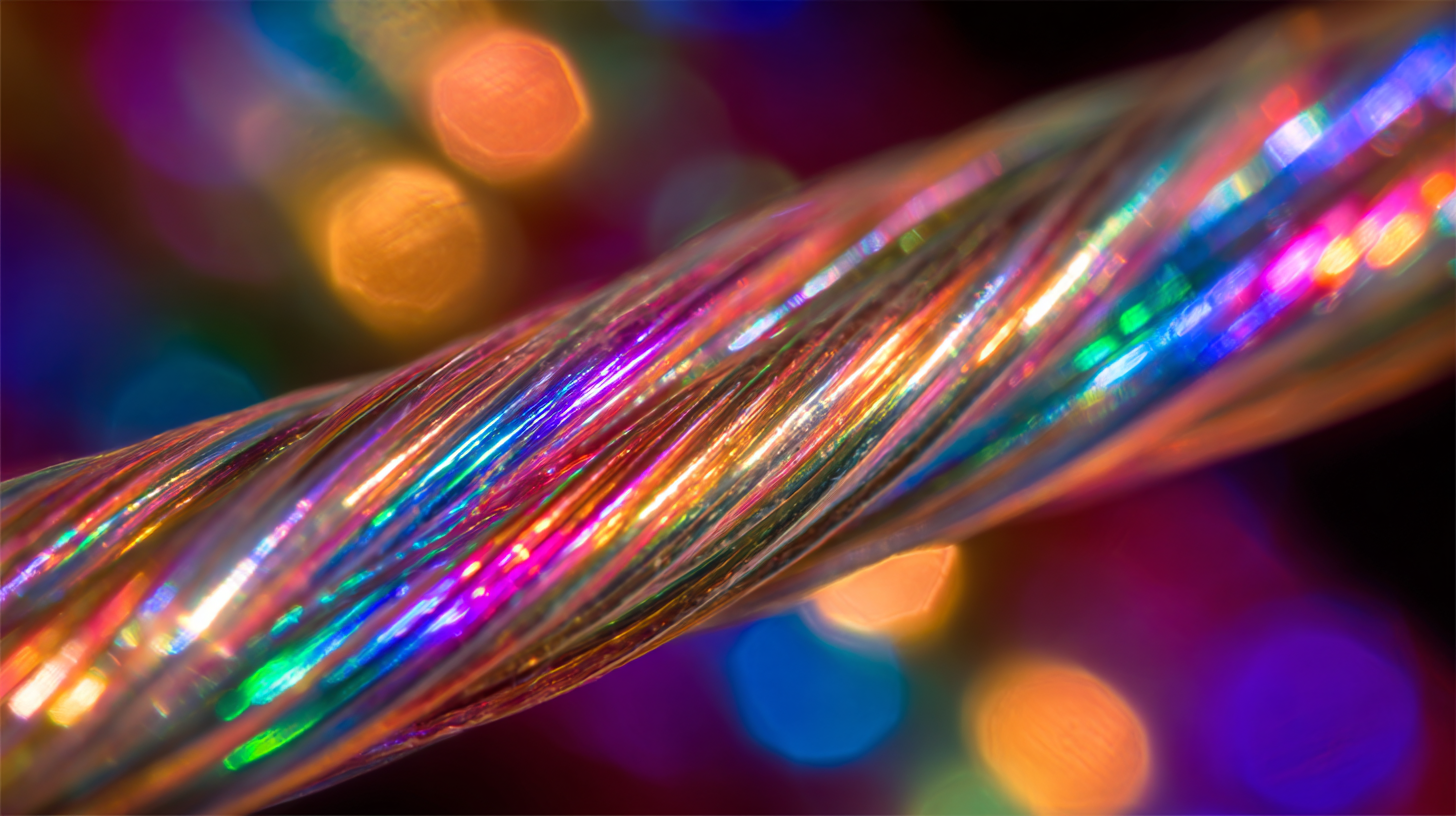

In the rapidly evolving landscape of modern electronics, the insatiable demand for efficient and reliable components has led to increased interest in innovative materials. One such material gaining prominence is Varnished Wire, renowned for its excellent electrical insulation, high heat resistance, and reduced dimensions. This article delves into the multifaceted benefits and diverse applications of Varnished Wire, elucidating how it enhances the performance of electrical devices and systems. By examining its role in various sectors, from consumer electronics to industrial machinery, we will explore how Varnished Wire not only contributes to the miniaturization of components but also improves energy efficiency. As we navigate through its characteristics and implementations, this guide aims to provide a comprehensive understanding of why Varnished Wire is becoming an indispensable element in the modern technological toolkit.

Varnished wire, also known as enameled wire, is a crucial component in modern electronics, characterized by its thin insulating layer of varnish or enamel that envelops a conductor. This coating serves multiple purposes: it prevents electrical shorts, enhances the wire's resistance to environmental factors, and improves its mechanical properties. The most commonly used materials for varnished wire include copper and aluminum, with copper being the preferred choice due to its superior conductivity. According to a recent market analysis by Research and Markets, the global enameled wire market is anticipated to reach USD 10.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of approximately 6.2% from 2021.

The composition of varnished wire varies depending on its intended application and desired characteristics. For instance, the insulation material can include polyester, polyamide, or polyester-imide, each offering different thermal and chemical resistances. This makes varnished wire particularly suitable for use in transformers, motors, and generators, where temperature stability and durability are paramount. The industry’s demand for efficient energy solutions is pushing manufacturers to innovate further, with advancements in insulation technology contributing to the enhanced performance of varnished wire products. The combination of electrical performance, thermal resistance, and flexibility makes varnished wire indispensable in the ever-evolving landscape of electronic devices.

In modern electronics, varnished wire has emerged as a crucial component due to its numerous advantages. One of the key benefits is its superior insulation properties, which significantly reduce the risk of short circuits and enhance the overall reliability of electronic devices. The varnish coating provides excellent dielectric strength, making it ideal for high-voltage applications where safety is paramount.

Another significant advantage of varnished wire is its thermal stability. This feature allows the wire to withstand high temperatures without degrading, which is essential in devices that generate heat. Furthermore, varnished wire is lightweight and flexible, making it easier to handle during assembly and manufacturable into compact designs, especially in consumer electronics where space is a premium.

Tips: When selecting varnished wire for your projects, consider the specific insulation class required for your application. Additionally, always check the temperature ratings to ensure they align with the operational conditions. Lastly, choosing the right varnish type can enhance performance, so consult manufacturers for the best options that suit your needs.

Varnished wire, particularly enamelled wire, plays a crucial role in modern electronics, offering both versatility and performance. One of the most common applications is in electric motors, where its high thermal resistance is essential. According to a report by Technavio, the global market for electric motors is expected to grow by over $23 billion from 2021 to 2025, driven largely by advancements in electric vehicle technology. Varnished wire's ability to withstand high temperatures and provide efficient insulation makes it a preferred choice in these high-performance applications.

Another significant use of varnished wire is in transformers and inductors. The epoxy-coated varieties are widely employed to reduce electrical losses and improve energy efficiency in these devices. Research conducted by MarketsandMarkets indicates that the transformer market is projected to reach $60 billion by 2025, with a notable increase in demand for varnished wire due to its insulation properties and ability to minimize heat generation. Additionally, in the realm of consumer electronics, varnished wire is integral to the development of compact and efficient circuit designs, enabling manufacturers to create smaller devices without sacrificing functionality.

The choice between varnished and unvarnished wire is critical in modern electronics due to their distinct performance characteristics. Varnished wire, coated with specialized insulation, provides enhanced thermal stability and corrosion resistance, making it suitable for applications where reliability is paramount. According to a report from Mordor Intelligence, the global market for varnished wire is expected to grow at a CAGR of 8.5% over the next five years, driven by increasing demands in high-frequency applications such as transformers and motors.

Comparatively, unvarnished wire, while cost-effective, lacks the protective coating that impedes oxidation and other environmental factors. This can lead to premature failure in operating conditions where moisture, heat, and other corrosive elements are present. The failure rates for unvarnished wire in such applications can be three to four times higher, as indicated by data from the International Electrotechnical Commission, emphasizing the importance of selecting varnished wire for longevity and performance in electronic components. As industries continue to prioritize durability and efficiency, the shift towards varnished wire becomes even more pronounced.

| Dimension | Varnished Wire | Unvarnished Wire |

|---|---|---|

| Electrical Insulation | Excellent | Limited |

| Heat Resistance | High | Moderate |

| Durability | Superior | Standard |

| Cost | Higher | Lower |

| Weight | Lightweight | Moderate |

| Application Areas | Transformers, Motors | General Wiring |

When working with varnished wire in electronics projects, it is crucial to adopt best practices for handling and installation to ensure optimal performance and longevity. First, always handle the wire with clean, dry hands or gloves to prevent any moisture or oils from contaminating the varnish. This protective coating is vital for the wire's insulation properties and overall functionality. Additionally, avoid sharp bends or kinks during installation, as these can compromise the wire's integrity and lead to premature failure.

Furthermore, proper preparation of the wire ends is essential for effective connections. Use a suitable stripping tool to carefully remove the varnish without damaging the wire strands beneath. Ensure that the exposed areas are clean, and if necessary, apply a compatible flux to enhance soldering. When connecting the varnished wire to terminals or other components, utilize high-quality solder that forms a strong bond while remaining compatible with the wire's material. By adhering to these best practices, you can optimize the performance and reliability of varnished wire in your electronics projects.