Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Enameled Aluminum Wire has increasingly gained traction in various electrical applications, owing to its superior conductivity and lightweight properties. According to a report by MarketsandMarkets, the global enameled wire market is projected to reach USD 20 billion by 2026, with the demand for Enameled Aluminum Wire expected to rise significantly due to its cost-effectiveness and efficiency. This wire type not only serves as an excellent conductor but also offers thermal resistance, making it ideal for high-temperature applications in industries such as automotive and renewable energy.

Industry expert Dr. Jane Thompson, a recognized authority in electrical materials, emphasizes the importance of Enameled Aluminum Wire in modern engineering. She states, “The performance characteristics of enameled aluminum wire are redefining the standards for energy efficiency in electrical systems.” This highlights how Enameled Aluminum Wire is not only meeting but exceeding the expectations of current technological advancements. As innovations continue to fuel its development, understanding the top benefits of Enameled Aluminum Wire becomes essential for engineers and manufacturers looking to optimize their electrical applications.

Enameled aluminum wire is gaining recognition for its role in enhancing electrical efficiency across various applications. One of the primary benefits it offers is the reduction in weight compared to traditional copper wire, which allows for streamlined designs and simplified installations. This lightweight attribute contributes to lower energy costs in transportation and setup while maintaining the necessary conductivity for electrical systems. As industries increasingly prioritize energy efficiency, the use of enameled aluminum wire becomes a strategic choice that aligns with modern sustainability goals.

Moreover, the excellent insulation properties of enameled aluminum wire improve energy efficiency by minimizing energy loss during transmission. The enamel coating provides effective thermal and electrical insulation, which helps to prevent overheating and energy dissipation. This characteristic allows for higher current carrying capabilities without the risk of degradation, ensuring devices operate optimally. In a world that demands constant advancements in energy efficiency, the integration of enameled aluminum wire can lead to significant savings and enhanced performance in electrical applications, making it a valuable material in modern engineering solutions.

In the realm of electrical applications, the comparison between enameled aluminum wire and traditional copper wire is increasingly relevant due to advancements in material science. Enameled aluminum wire boasts a lower density than copper, providing a significant weight advantage. Weighing approximately 1/3 of copper, enameled aluminum wire allows for easier handling and installation, especially in large-scale projects where reducing overall weight can lead to substantial cost savings in structural support and transportation. According to a study published by the International Electrotechnical Commission, switching from copper to aluminum can result in a weight reduction of 50% in specific applications, enhancing efficiency.

Performance-wise, enameled aluminum wire has shown promising electrical conductivity, though it typically offers around 60% of the conductivity of copper. However, when combined with a proper insulation system, aluminum wire can maintain excellent performance for various electrical applications. Recent reports have indicated that the efficiency loss in aluminum wiring can be mitigated through refined application techniques, making them a viable alternative to copper in many scenarios. The National Electrical Manufacturers Association reports that the global market for aluminum wires is projected to grow by 8% annually, indicating a growing recognition of their effectiveness and cost-efficiency in the electrical industry. Thus, the choice between enameled aluminum and copper wire is increasingly driven by the balance of performance characteristics and economic factors.

| Benefit | Enameled Aluminum Wire | Copper Wire |

|---|---|---|

| Weight | Lighter than copper, easier to handle | Heavier, may require stronger support structures |

| Cost | More cost-effective for large-scale applications | Generally higher material cost |

| Conductivity | Lower conductivity (approximately 61% of copper) | Higher conductivity |

| Corrosion Resistance | Better resistance due to enamel coating | Prone to oxidation without protective coatings |

| Thermal Conductivity | Lower than copper but sufficient for many applications | Higher thermal conductivity |

| Flexibility | More flexible, easier to bend without fatigue | Less flexible, can be stiffer |

| Usage in High-Frequency Applications | Preferred for RF applications due to lower skin effect | Can perform well but less advantageous at high frequencies |

| Environmental Impact | Recyclable material | Recyclable but with higher mining impact |

| Electrical Resistance | Higher resistance can be a drawback in some applications | Lower resistance overall |

| Heat Dissipation | Can be less effective compared to copper | More effective heat dissipation |

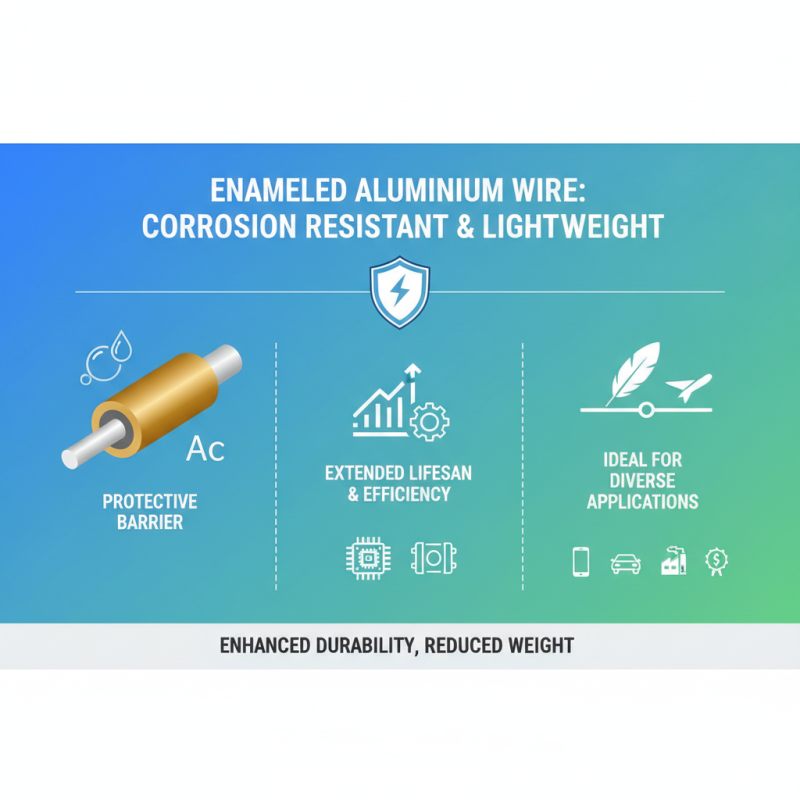

Enameled aluminum wire has garnered significant attention in electrical applications, primarily due to its excellent corrosion resistance properties. The enamel coating serves as a protective barrier against environmental factors, such as moisture and corrosive agents, which can lead to wire degradation. This enhanced durability not only prolongs the lifespan of electrical components but also ensures efficient performance in harsh conditions. The lightweight nature of aluminum further complements its resistance to corrosion, making it an ideal choice for various applications, from consumer electronics to industrial machinery.

When selecting enameled aluminum wire for specific applications, consider environmental factors such as humidity, temperature fluctuations, and exposure to chemicals. This will help in choosing the right type of enamel coating that suits your needs. Additionally, ensure proper installation techniques are employed to maintain the protective properties of the wire, thereby maximizing its lifespan.

It's also vital to recognize that regularly inspecting and maintaining electrical systems can prevent potential corrosion-related failures. Implementing protective measures, such as using suitable junction boxes or conduits, can further enhance the wire's durability, ensuring reliability in electrical performance. By understanding the key properties of enameled aluminum wire, you can make informed decisions for your electrical projects.

The cost-effectiveness of enameled aluminum wire in large-scale electrical projects is becoming increasingly significant in today's competitive market. According to a report from the International Wire and Cable Trade Association, aluminum wire can reduce material costs by approximately 30% compared to copper counterparts. This cost advantage is particularly beneficial for extensive electrical projects, where budget overruns can be detrimental to overall profitability. The lower density of aluminum also means that projects require less structural support, translating to additional savings in construction expenses.

Moreover, enameled aluminum wire offers excellent electrical properties, leading to improved energy efficiency. A study published in the Journal of Electric Power Systems Research highlighted that in high-voltage applications, aluminum wire exhibits lower resistance and better performance when adequately insulated with enamel coatings. This enhanced efficiency can lead to reduced energy consumption, further contributing to overall cost savings. By investing in enameled aluminum wire, companies can not only lower initial expenditure but also enjoy long-term operational benefits, making it a smart choice for electrical projects that demand both performance and budget adherence.

Enameled aluminum wire plays a pivotal role in renewable energy systems, primarily due to its lightweight, excellent conductivity, and resistance to corrosion. These properties make it an ideal choice for applications such as wind turbine generators and solar panel connections. In wind energy systems, enameled aluminum wire is utilized to connect the rotor to the generator, where its reduced weight helps minimize the overall turbine design, enhancing efficiency and reducing material costs. Additionally, the wire's insulating enamel protects it from environmental factors, ensuring long-term durability in harsh climates.

In solar energy applications, enameled aluminum wire is crucial for interconnecting solar cells within photovoltaic modules. Its superior conductive properties allow for efficient energy transfer and minimize energy losses, ultimately improving the overall efficiency of solar energy systems. Furthermore, the enamel insulation provides excellent protection against moisture and UV exposure, thereby increasing the lifespan of solar installations. As the demand for renewable energy continues to grow, enameled aluminum wire is set to become an even more integral component due to its cost-effectiveness and performance advantages in these sustainable technologies.