Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

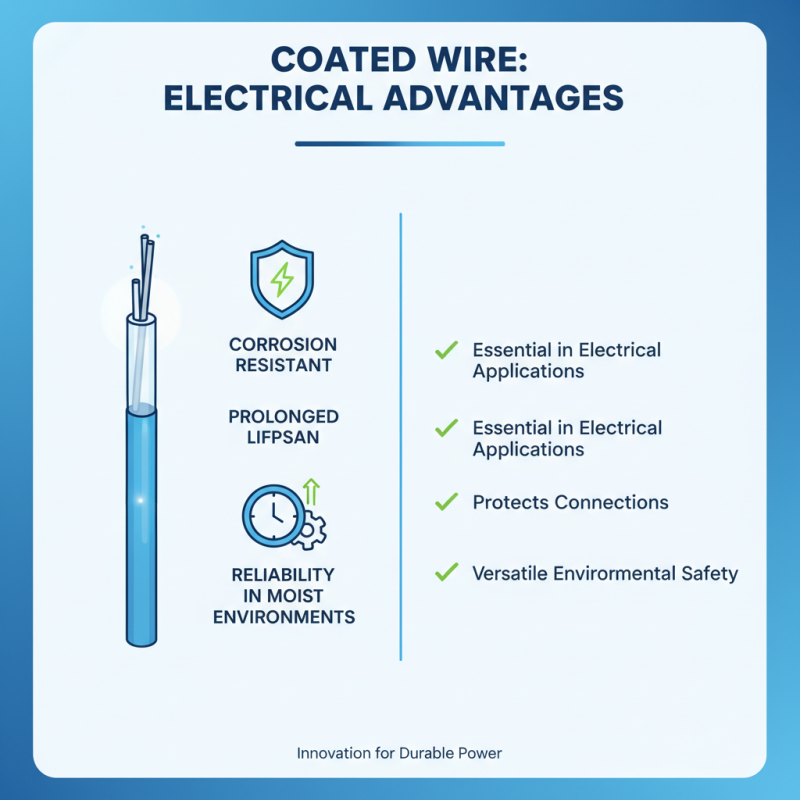

Coating Wire has become an essential component in various electrical and industrial applications. This innovation offers numerous benefits over traditional wiring methods. The versatility of Coating Wire allows it to excel in challenging environments, where durability and reliability are crucial.

In industries such as manufacturing, transportation, and telecommunications, Coating Wire proves its worth. It resists harsh chemicals and extreme temperatures. However, some may overlook its advantages. They might assume that standard wire solutions are sufficient for their needs. This perspective can lead to failures or inefficiencies.

Embracing Coating Wire requires a shift in mindset. It is not just about functionality; it’s about securing long-term performance. Investing in Coating Wire can improve safety and reduce maintenance costs. Adopting this solution reflects a commitment to quality and resilience. It is worth evaluating and reconsidering your current wiring choices.

Coated wire is becoming essential in electrical applications. One major advantage is its resistance to corrosion. This feature prolongs the lifespan of electrical connections. It keeps wires safe in various environments, including moist areas.

Another benefit lies in its insulation properties. Coatings provide excellent electrical insulation. This minimizes the risk of short circuits and electrical fires. Without proper insulation, wires can pose significant safety hazards. The layers of coating also allow for customization based on the specific needs of a project.

However, not all coated wires are created equal. Some coatings may wear off faster than others. This can lead to premature failures. It's crucial to assess the environment and potential stressors for each application. A well-informed choice of coated wire can enhance reliability, yet it requires careful consideration.

Coated wire is vital for electrical and industrial applications. The type of coating significantly affects wire performance. Common coatings include PVC, polyurethane, and nylon. Each type serves specific functions. For example, PVC is popular for insulation. It offers good dielectric properties and abrasion resistance. However, its flexibility can be limited.

Nylon coatings, on the other hand, provide excellent toughness and resistance to chemicals. They can withstand harsher environments. Yet, the manufacturing process can be more complex. Polyurethane coatings offer a balance between flexibility and durability. This makes them ideal for demanding applications.

Choosing the right coating is not always straightforward. One must consider environmental factors and mechanical stress. A wrong choice can lead to failures. It's essential to evaluate the specific requirements of each application. Sometimes, the best solution involves a bit of trial and error. Understanding each coating's pros and cons is crucial for optimal wire performance.

The electrical and industrial sectors have seen significant advancements with the introduction of coating wire solutions. These specialized wires are vital for various applications. Industries such as automotive manufacturing benefit from enhanced insulation properties. Coated wires improve durability and performance in severe conditions. This can lead to more reliable vehicles on the road.

In electronics, coating wire is crucial. It provides protection against moisture and chemicals. Many devices rely on these wires for efficient operation. Subpar wire choices often lead to failures. The potential risks in critical systems cannot be underestimated. It’s essential for producers to evaluate their supplier’s offerings carefully.

Another important sector is construction. Coated wires help ensure safety and longevity. They perform well in different environments. However, not all coated options meet the required standards. It is vital to scrutinize certifications and quality control. This industry faces challenges in sourcing high-quality materials consistently. Effective solutions are necessary to avoid future setbacks.

When selecting coated wire for electrical and industrial applications, several factors come into play. The type of coating is crucial. Different coatings offer varying degrees of protection against environmental elements. For instance, some coatings resist corrosion better than others. This can affect the wire's longevity and performance in harsh settings.

Wire gauge also matters. A thicker wire can handle more current but can be less flexible. This is important in applications where the wire needs to bend or fit into tight spaces. Additionally, the insulation type influences the durability. Some materials are more heat-resistant, while others can withstand oily or wet environments. Consider the specific conditions where the wire will be used.

Furthermore, understanding the intended application is key. Different industries have distinct requirements. A wire meant for outdoor use should have different properties than one used indoors. Don't forget to think about compatibility with other materials in your project. It’s not always easy to find the perfect match. Testing and adjustments may be necessary. These factors can lead to challenges but also opportunities for improvement. Making informed choices will ultimately lead to better performance and reliability in your applications.

| Factor | Description | Examples |

|---|---|---|

| Material | The type of material used for the coating affects durability and flexibility. | PVC, Polyethylene, Teflon |

| Temperature Resistance | Wires need to withstand high or low temperatures based on application. | -40°C to +200°C |

| Chemical Resistance | Resistance to chemicals can determine suitability for specific environments. | Acids, Oils, Solvents |

| Electrical Insulation | The insulation properties prevent electrical leakage and ensure safety. | High dielectric strength |

| Flexibility | A flexible coat allows easier installation and movement. | Stranded wire vs solid wire |

| UV Resistance | Protection from UV rays extends the lifespan of exposed wires. | Outdoor applications |

Coated wires play a crucial role in the industrial sector. They resist corrosion and wear. This makes them ideal for long-term use. In environments where moisture and chemicals are common, coated wire outperforms uncoated options. The protective layer can significantly extend the lifespan of the wire. Yet, it’s not entirely foolproof. Regular inspections are still necessary to ensure integrity.

In addition to durability, maintenance is key. Users should monitor the condition of coated wires routinely. Even small damages can lead to significant failures. Operators often overlook minor wear, assuming the coating will protect effectively. This misguided trust can lead to costly downtime. Learning to identify wear and tear is vital.

Another aspect to consider is the installation process. Incorrectly installing coated wires can negate their advantages. Proper training and guidelines should be provided to ensure optimal performance. Choosing coated wire should come with an understanding of its strengths and weaknesses. It’s all about finding a balance to optimize both efficiency and safety.