Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

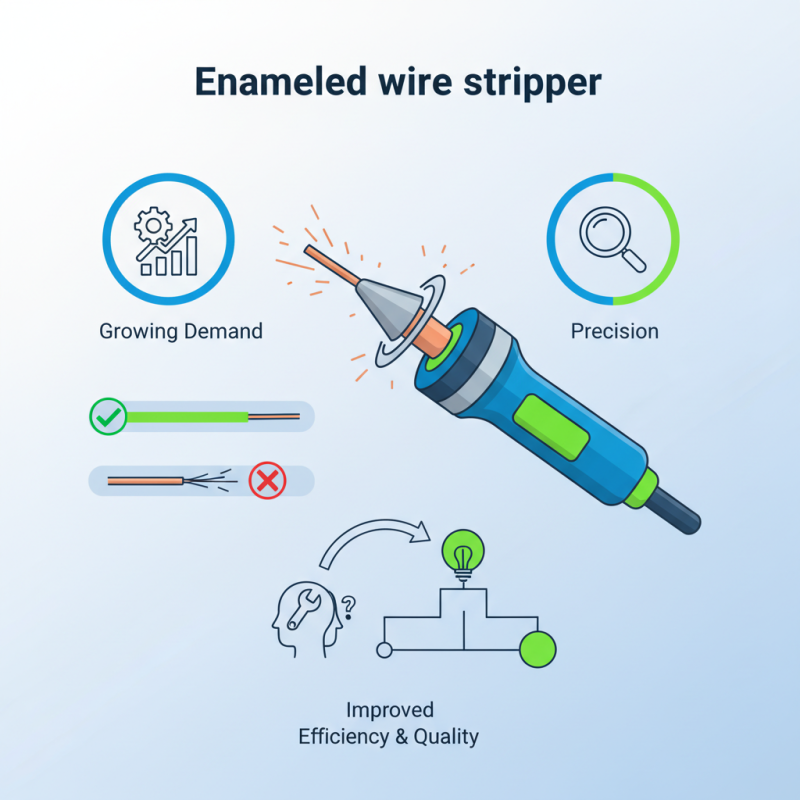

The Enameled Wire Stripper is an essential tool in the electrical industry. According to a recent report by the Global Wire Equipment Association, the demand for precision wire stripping tools has grown by 15% annually. This statistic highlights the critical role these devices play in various manufacturing processes.

Industry expert John Smith, who has over 20 years of experience, states, "An Enameled Wire Stripper is vital for achieving clean and efficient wire connections." This statement underscores the importance of this tool in ensuring reliable electrical performance.

Despite its popularity, many users still face challenges in optimizing its functionality. Improper use can lead to wire damage or malfunction. Understanding how to effectively utilize an Enameled Wire Stripper is important for both experienced technicians and novices alike. Addressing these issues can significantly improve production quality and efficiency.

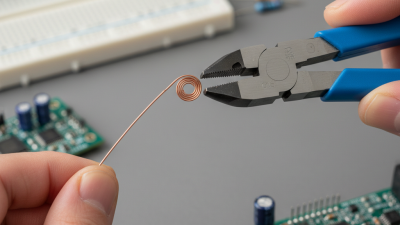

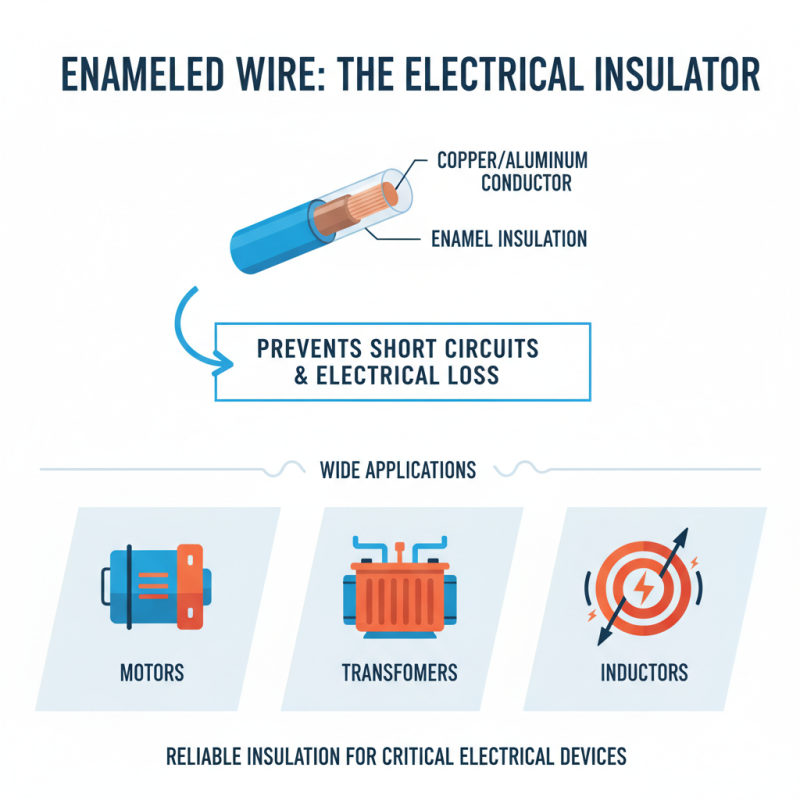

Enameled wire is a vital component in electrical engineering. It consists of copper or aluminum wire coated with a thin layer of enamel. This coating provides insulation, preventing short circuits and electrical loss. Enameled wire is widely used in various applications, including motors, transformers, and inductors. These devices require reliable insulation due to their operational demands.

In electrical engineering, the applications of enameled wire are extensive. For instance, in motors, the elementary copper wire helps create electromagnetic fields. Without the enamel, the efficiency would drop significantly. Moreover, transformers use it to keep energy loss at bay. Enameled wire is not only durable but also helps in minimizing interference.

**Tips:** When stripping enameled wire, use a wire stripper designed for this purpose. It can save time and avoid damage. Be mindful of the coating thickness; an improper strip could lead to exposure of the copper. Always double-check connections to ensure efficient electrical conductivity.

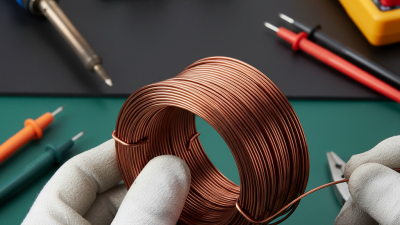

An enameled wire stripper is a specialized tool. It removes the insulation from enameled wire efficiently. The tool is crucial for electricians and engineers. According to industry reports, improper insulation removal can lead to increased failure rates in electrical components by up to 30%. This emphasizes the need for precision in wire preparation.

Understanding how an enameled wire stripper works is vital. The device typically features cutting blades that target the enamel coating without damaging the wire underneath. Many users struggle with finding the right pressure; too much force can snap the wire. Commonly, technicians recommend a firm yet gentle grip. A study by a leading wiring association found that nearly 40% of wire damage is attributed to poor stripping techniques.

Maintenance of the tool is essential for performance. Regular cleaning helps maintain its effectiveness. Many users overlook this step, leading to decreased efficiency over time. Reports indicate that a well-maintained stripper can last twice as long as one that is neglected. Attention to detail with an enameled wire stripper can prevent costly mistakes in wiring projects.

Enameled wire strippers are essential tools in electrical work. They strip the insulation off enameled copper wire. This makes it easier to connect wires to terminals. Understanding their components can enhance effectiveness.

One crucial part is the blade. The blade is often made of hardened steel. It must be sharp to peel off enamel without damaging the wire. The stripping notch is another key feature. It matches the wire gauge, ensuring a clean cut. Adjustability is important too. Some models allow users to modify how much insulation is removed.

The design can vary significantly. Compact models are great for tight spaces. Larger strippers may have built-in cutters for convenience. However, not all designs are user-friendly. Some can be cumbersome or difficult to operate. A reliable grip is needed for precision. Not everyone finds the right fit for their hands. Functionality and comfort should always be balanced.

| Component | Description | Function |

|---|---|---|

| Cutting Blades | Sharp blades designed to cut through enamel insulation. | Used to remove the insulation from enameled wires. |

| Adjustment Mechanism | A system to adjust the depth and pressure of the cut. | Allows for precise stripping based on wire gauge. |

| Guide Tubes | Hollow tubes that ensure accurate wire placement. | Guides the wire into the cutting area for uniform stripping. |

| Handle Grip | Ergonomically designed grip for user comfort. | Provides better control during operation, reducing fatigue. |

| Safety Lock | A mechanism that locks the stripper when not in use. | Prevents accidental injury or blade damage. |

Using an enameled wire stripper can seem challenging. This tool is essential for safely removing the insulation from enameled wires. Understanding its operation is key to effective usage.

To start, secure the wire stripper in one hand. Position the enameled wire in the jaws, aligning it with the cutting edge. Apply gentle pressure and squeeze the handles together. This action scrapes off the enamel coating. You may need to adjust the wire position for complete removal. Be patient; it may not strip perfectly on the first try.

**Tips:** Always check the wire type before using. Some wires require specific handling. If the enamel doesn’t come off easily, don’t force it. Instead, carefully readjust the wire. A less aggressive approach often yields better results. Practice on scrap wires to build confidence and skill.

After stripping, examine the wire closely. Look for any nicks or damage. If the wire is compromised, reconsider your technique. Rushing can lead to mistakes. Take your time and focus on precision.

Using an enameled wire stripper can be a straightforward task, but safety is crucial. When working with electricity, even minor mistakes can lead to serious consequences. Always wear safety goggles to protect your eyes from flying debris. Ensuring that your workspace is clean and well-lit can help prevent accidents.

Before you start stripping the wire, check the tools for any damage. A dull blade can slip and cause injury. Angle the stripper correctly for a clean cut. Pull with a steady, gentle force. Avoid excessive pressure; it can break the wire instead of stripping it. If you feel resistance, stop and adjust your grip.

Storing your enameled wire stripper in a dry place prolongs its life. Regularly cleaning it helps maintain performance. However, many forget this step, leading to rust or damage. Always double-check that the tool is free from debris before use. If ever in doubt, consult reference materials before proceeding.