Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

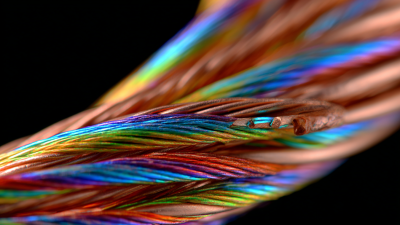

Soft Coated Wire is a remarkable innovation in wire production. Its unique coating provides enhanced protection and flexibility, making it ideal for various applications. The use of this specialized wire spans multiple industries, including construction, automotive, and electronics.

In construction, Soft Coated Wire plays a vital role in reinforcing structures. Its ability to resist corrosion prolongs the life of buildings. Meanwhile, in automotive manufacturing, it is essential for wiring harnesses that require durability and flexibility. The lightweight nature of this wire simplifies installations, a plus in modern vehicles.

Despite its advantages, there are still unanswered questions. For instance, how does this wire hold up under extreme temperatures? Its varied quality also raises concerns about consistency. As industries continue to explore its potential, the discourse surrounding Soft Coated Wire must expand. A deeper understanding could lead to innovations we have yet to imagine.

Soft coated wire is a specialized type of wire with a protective layer that enhances both durability and flexibility. Typically made from steel, the wire undergoes coating processes using various materials like PVC or nylon. This coating not only prevents corrosion but also provides insulation, making it suitable for diverse applications. According to a recent industry report, the global market for coated wires is projected to grow at a CAGR of 5% from 2023 to 2030.

In the construction and manufacturing sectors, soft coated wire is widely used. Its lightweight nature and resistance to environmental factors make it an ideal choice for building reinforcement. Additionally, in the automotive industry, the wire is used for harnesses and connections, where electrical insulation is critical. Studies show that the electrical efficiency of components increases by nearly 10% when using insulated wires.

While soft coated wire offers numerous advantages, it is not without limitations. Some users report issues with the coating, such as peeling or wear over time. This can lead to exposure of the core wire and compromise performance. Industry professionals suggest regular inspections to ensure longevity. Understanding these factors can optimize its uses and lead to better project outcomes.

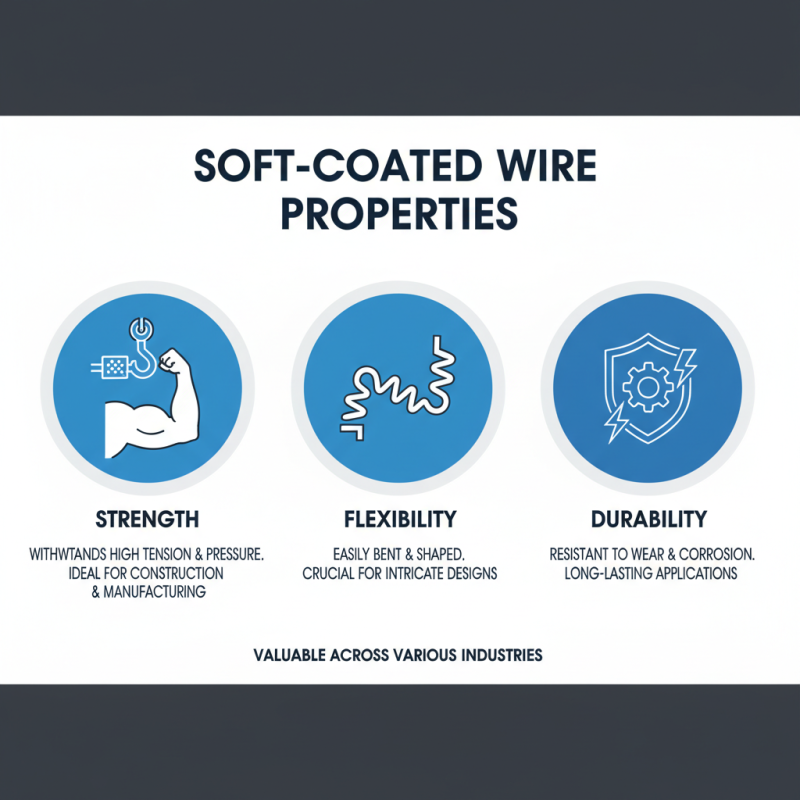

Soft coated wire is known for its unique properties that make it valuable across various industries. One major advantage is its strength. This wire can withstand significant tension and pressure without breaking. This makes it ideal for construction and manufacturing applications. Moreover, its flexibility allows it to be bent and shaped easily. This is crucial for use in intricate designs or installations where precise angles are required.

Durability is another key property. Soft coated wire resists wear and corrosion, enhancing its longevity. This quality is particularly beneficial in outdoor environments. However, users need to ensure that the wire is properly maintained. Regular checks can prevent potential issues, especially in harsh conditions.

Tips: Always consider the specific requirements of your project. Choosing the right diameter of wire is essential for stability. Also, remember to inspect connections and joints over time. This will help maintain overall performance. A little attention can go a long way in prolonging the life of soft coated wire.

Soft coated wire is a versatile material widely used in the automotive industry. Its flexibility allows engineers to create components that adapt to various needs. For example, it can be shaped into intricate designs for wire harnesses. These harnesses connect different electrical systems in vehicles, ensuring smooth operation and safety.

Another essential application is in the manufacturing of suspension systems. Soft coated wires are used to produce springs and shock absorbers. These components play a vital role in providing comfort while driving. The softness of the coating helps prevent wear and tear, ensuring longevity and reliability. Yet, the manufacturing process can sometimes lead to inconsistencies. This raises questions about quality control.

Soft coated wire is also utilized in airbag systems. The wire's resilience is crucial for activating bags quickly during accidents. However, there are challenges in meeting safety standards. Manufacturers must always evaluate their production methods. Sometimes, minor defects can cause significant issues, highlighting the need for careful monitoring. The automotive industry continues to evolve, and so must the processes involving soft coated wire.

Soft coated wire plays a crucial role in the electronics sector. This wire, designed with a softer outer layer, provides flexibility and resilience. As per industry reports, the global market for soft coated wire in electronics was estimated at $1.5 billion in 2022, with a projected growth rate of 10% annually. The demand is driven by the increasing need for lightweight and durable materials in device manufacturing.

One key advantage of soft coated wire is its exceptional conductivity. It minimizes resistance, ensuring efficient energy transfer in devices. This is crucial for the performance of electronics, particularly in high-frequency applications. Moreover, the soft coating protects against wear and corrosion, extending the longevity of electronic components. However, manufacturers must balance durability with flexibility. A softer coating can sometimes lead to issues in high-stress applications.

Another aspect to consider is the environmental impact. While soft coated wire enhances performance, sourcing materials responsibly is vital. Industry reports highlight that up to 25% of raw materials used in wire production can be recycled. This is a step towards sustainability, but it’s often overlooked in the rush for innovation. Engineers must reflect on how choices today impact future technology.

Soft coated wire is gaining traction across various industries due to its unique properties. Recent reports indicate the global market is expected to grow significantly. For instance, a 2023 market analysis shows a projected CAGR of 5.6% for soft coated wire applications in electrical and telecommunications sectors. This growth is driven by increasing demand for reliable, flexible, and corrosion-resistant materials.

Innovations in soft coated wire technologies are addressing specific challenges. Engineers are focusing on improving tensile strength while reducing weight. This is crucial for the automotive and aerospace industries. As manufacturers seek lighter components, the demand for advanced soft coated wires rises. Furthermore, biocompatible soft coated wires are emerging in the medical field, providing safer alternatives for implants.

Despite the advancements, there are challenges that need attention. For example, production costs can be high due to the specialized processes involved. Additionally, the market faces issues with standardization and quality control. As industries continue to adapt, these factors will require ongoing evaluation. Future innovations could refine manufacturing techniques, leading to lower costs and enhanced performance. This is a critical area for companies aiming to stay competitive.