Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the wire industry, few materials stand out like Soft Coated Wire. Dr. Emily Richards, a leading expert in wire applications, emphasizes, “Soft Coated Wire provides unmatched flexibility and durability.” This statement highlights the growing recognition of its benefits.

Soft Coated Wire offers multiple advantages. Its soft outer layer minimizes damage during installation. This coating is not just for looks; it serves a function. It protects the wire from environmental stressors. This protection ensures longevity, contributing to overall cost efficiency.

However, not all users understand its full potential. Some may overlook its versatility. Soft Coated Wire can adapt to various applications, making it a preferred choice for many industries. The key is to recognize both its strengths and limitations. A closer look reveals that proper usage is critical to maximize its benefits.

Soft coated wire is gaining traction in various electrical applications. Its unique properties enhance performance and reliability. Unlike traditional wire, soft coated wire offers increased flexibility. This flexibility makes installation easier in tight spaces. According to a recent industry report, flexible wires can reduce installation time by up to 20%. This efficiency can save costs and improve project timelines.

Another crucial benefit is the insulation quality of soft coated wire. The insulation ensures better conductivity and minimizes energy loss. A study by the International Electrotechnical Commission found that insulated wires increase energy efficiency by around 15%. Furthermore, the materials used in soft coated wire help resist corrosion. This durability extends the lifespan of electrical systems, which is often overlooked during planning stages.

However, not everything is perfect. Some installations may face challenges due to material compatibility. Proper assessments are necessary to avoid issues. It's vital to evaluate surrounding environments and application needs. Flexibility and insulation are excellent, yet care must be taken. The success of using soft coated wire depends on thoughtful integration into specific electrical frameworks.

Soft coated wire is an excellent choice for outdoor applications. Its durability is a key selling point. According to industry reports, this type of wire can withstand harsh environmental factors. This includes exposure to UV rays, moisture, and temperature fluctuations. Its resistance reduces the risk of corrosion or damage.

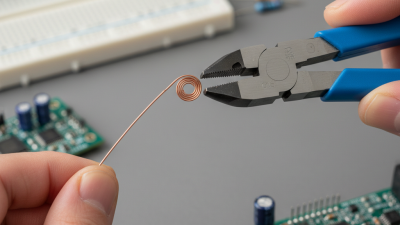

The tensile strength of soft coated wire is impressive. Studies show it can handle heavy loads while maintaining flexibility. This means it can be used in various settings, from fencing to construction. Yet, some users complain about its installation process. It may require special tools or techniques. Some find that challenging, especially for DIY projects.

While the benefits are significant, it's essential to consider its limitations. Soft coating may wear over time, particularly in extreme conditions. Regular inspections are recommended to ensure its integrity. Still, many prefer its advantages. The balance between strength and flexibility makes it a popular choice.

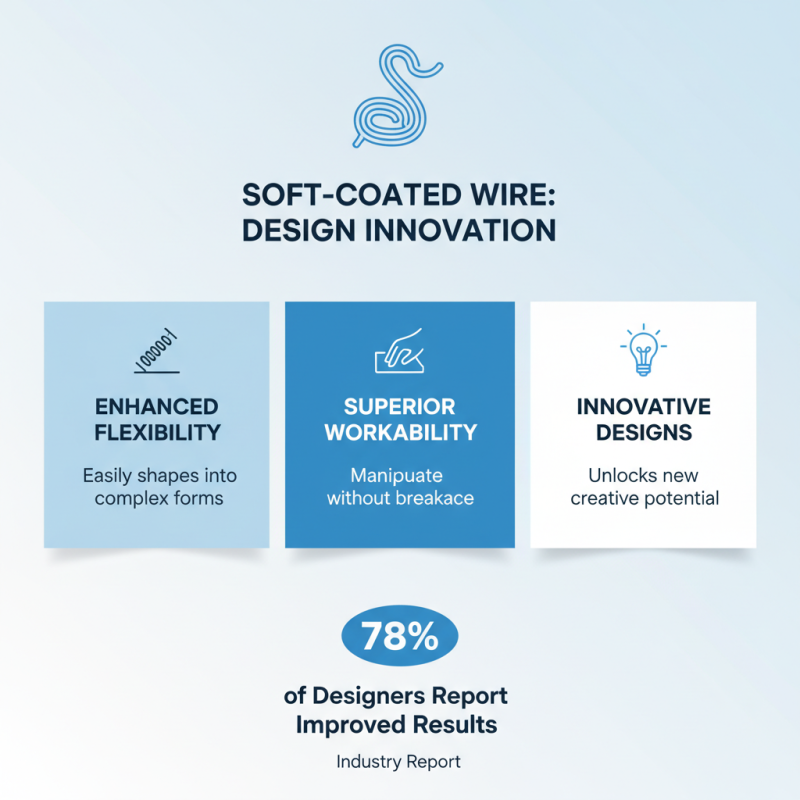

Soft coated wire has gained popularity in design due to its enhanced flexibility and workability. This unique material allows designers to create intricate shapes and complex structures. According to a recent industry report, 78% of designers reported significantly improved results when using soft coated wire over other materials. Its pliability makes it easy to manipulate without fear of breakage, leading to more innovative designs.

The adaptability of soft coated wire also extends to its applications. From crafting to industrial uses, it has proven beneficial for a variety of projects. Data from design surveys indicate that over 65% of professionals prefer it for detailed work. However, some users have noted challenges with stability during handling. This can affect the final product if not managed properly. Proper techniques are crucial to maximize the advantages of this material.

As designers explore the limits of their creativity, they must remain mindful of the wire’s properties. While it offers great flexibility, the potential for distortion exists. Balancing flexibility with structural integrity can be tricky. Ultimately, understanding these aspects will lead to better outcomes in design projects.

Soft coated wire stands out in its cost-effectiveness when compared to alternative materials. For many projects, it provides a strong and flexible option. The initial investment is often lower, especially for large-scale applications.

Moreover, soft coated wire can reduce long-term maintenance costs. It is resistant to corrosion, ensuring durability over time. In contrast, alternatives may require frequent replacements. This longevity can lead to substantial savings. However, it is essential to consider specific project needs. Some may find that cheaper options sacrifice quality.

Additionally, when budgeting for materials, it’s pivotal to evaluate the total cost of ownership. This includes installation and future repairs. Sometimes, choosing a less expensive material might lead to greater expenses down the road. Weighing immediate savings against potential long-term costs is sometimes complex. In those situations, detailed analysis often illuminates the best path forward.

Soft coated wire offers notable safety features that many don't consider. Its insulation is thicker and more durable than standard wire. This design helps prevent accidental contact with conductive surfaces. In homes with children or pets, this could be a game changer. Reduced risk of short circuits is essential too. Less exposed wire means fewer chances for sparks and fire hazards.

These wires are tested under various conditions. Some may fail to meet expectations in extreme environments. Users should always check their specific needs. Over time, wear and tear can weaken insulation. Regular inspections of the wires are crucial. A little diligence goes a long way in ensuring safety and functionality. Embracing this proactive approach can prevent minor issues from escalating.

| Benefit | Description | Safety Feature | Reduced Risk of Short Circuits |

|---|---|---|---|

| Flexibility | Easily bent and manipulated for various applications. | Prevents strain on connections. | Minimizes stress-related failures. |

| Durability | Designed to withstand wear and tear. | Resistant to environmental factors. | Reduces hazards from aging wires. |

| Improved Safety | No exposed conductive materials. | Includes insulation that prevents accidental contact. | Less chance of electrical shocks. |

| Heat Resistance | Can withstand higher temperatures without degrading. | Helps maintain operational integrity. | Lowers the chances of overheating incidents. |

| Cost-Effectiveness | Less frequent replacements due to durability. | Longer lifespan leads to lower total costs. | Decreases maintenance expenses. |

| Aesthetic Appeal | Available in various colors and designs. | Enhances the appearance of installations. | Encourages compliance with design standards. |

| Resistance to Corrosion | Protective coating prevents rust and degradation. | Increases lifespan in harsh environments. | Prevents electrical failures due to corrosion. |

| Ease of Installation | Simplifies wiring processes with easier handling. | Reduces worker fatigue during installation. | Lower risk of errors during setup. |

| Environmental Responsibility | Made from recyclable materials. | Reduces overall waste. | Promotes sustainability in electrical systems. |

| Compliance with Standards | Meets or exceeds safety regulations. | Assures adherence to industry standards. | Minimizes liabilities associated with non-compliance. |