Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In today's competitive manufacturing landscape, Eaw Wire Coating stands out due to its remarkable benefits. The global wire coating market is projected to reach $35 billion by 2025, showcasing the rising demand for advanced coatings. Industries prioritize durability and efficiency, making Eaw Wire Coating a crucial choice for many.

This coating offers enhanced resistance to corrosion and wear, which is vital for long-term applications. A report from the Coating Federation states that 45% of production issues stem from inadequate wire protection. Therefore, using Eaw Wire Coating can significantly reduce downtime and maintenance costs.

However, not all coatings are created equal. It’s essential to choose the right coating type to suit specific applications. Some businesses overlook this aspect, potentially leading to subpar results. Understanding the unique advantages of Eaw Wire Coating can help make informed decisions, safeguarding your operations and ensuring quality output.

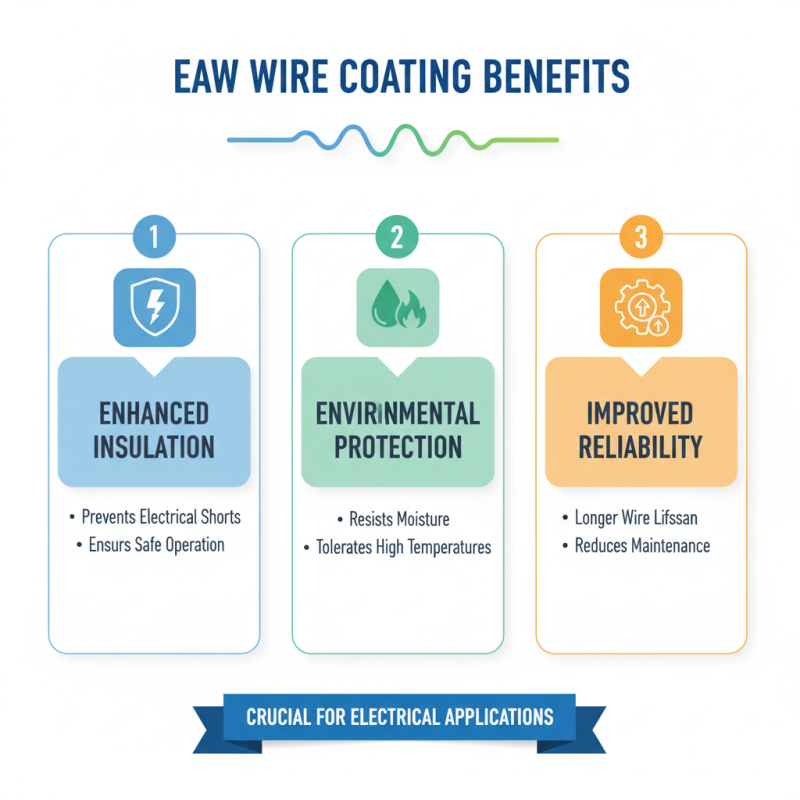

Eaw wire coating offers numerous advantages for electrical applications. One significant benefit is enhanced insulation. This protective layer prevents electrical shorts and ensures safe operation. Proper insulation is crucial, especially in environments with moisture or high temperatures.

Another benefit is increased durability. Coated wires resist abrasion and corrosion. They can withstand harsh conditions better than uncoated alternatives. This longevity can lead to lower maintenance costs. Fewer replacements are necessary over time.

Improved flexibility is also a notable advantage. The coating allows the wire to bend, twist, and adapt without breaking. This flexibility helps during installation. However, it is not always easy to achieve the right balance between flexibility and durability. Some coatings may wear down quicker than expected. It's essential to assess specific needs before choosing a coating type.

Coated wires are becoming essential in various industries. Their enhanced durability is one of the primary benefits. According to a recent report, coated wires can last up to three times longer than uncoated ones. This improvement can significantly reduce replacement costs. It's a crucial factor for manufacturers focused on long-term investment.

The coating acts as a protective barrier. It prevents corrosion caused by environmental factors. Data shows that wires exposed to harsh conditions suffer a 15% performance drop each year. Coated wires resist this decline effectively. However, not all coatings provide the same level of protection. Some coatings can wear away faster than anticipated, highlighting the need for careful selection.

Longevity is evident but not guaranteed. While many coated wires offer improved performance, some may fall short under specific circumstances. For instance, excessive heat can compromise the protective layer. This risk requires companies to thoroughly assess their environment. In doing so, they can maximize the lifespan of their coated wires.

| Benefit | Description | Expected Impact |

|---|---|---|

| Enhanced Durability | Coating significantly increases the wire's resistance to environmental factors. | Reduced maintenance costs and extended lifespan. |

| Corrosion Resistance | Protective coating prevents rust and deterioration over time. | Improved performance in harsh environments. |

| Electrical Insulation | Insulating properties reduce the risk of electrical shorts and failures. | Increased safety and reliability of electrical systems. |

| Temperature Resistance | Coatings designed to withstand extreme temperatures without degradation. | Enhanced performance in thermal cycling applications. |

| Aesthetic Benefits | Available in various colors and finishes, improving visual appeal. | Better integration with design requirements in installations. |

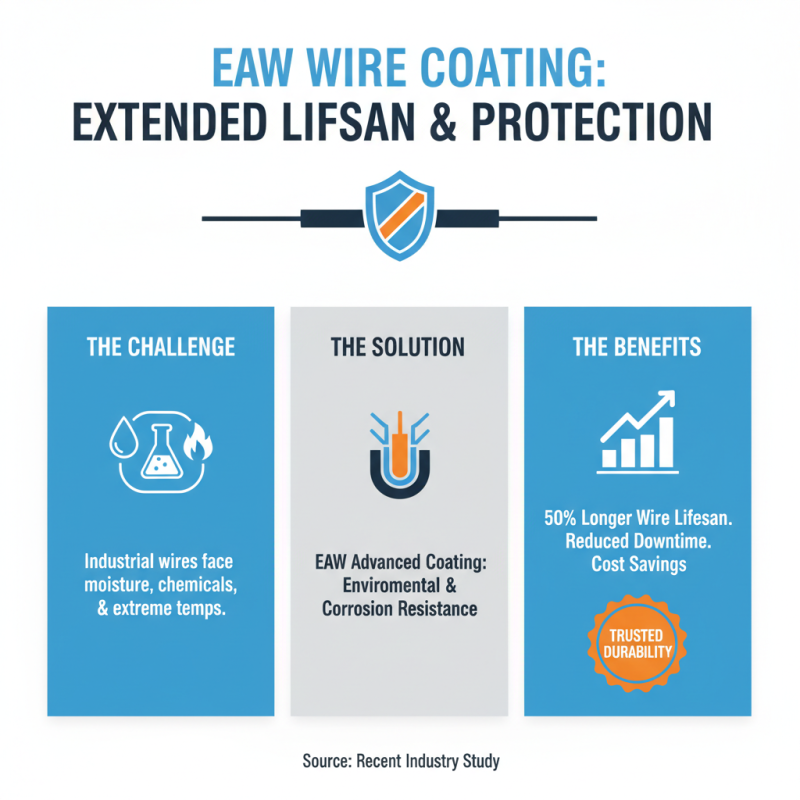

Eaw wire coating offers significant benefits, especially in improving resistance to environmental factors and corrosion. In industrial settings, wires are often exposed to moisture, chemicals, and temperature fluctuations. The right coating can extend the lifespan of wires by protecting them from these harsh conditions. A recent study showed that wires with advanced coatings can last up to 50% longer than uncoated wires.

Corrosion is a major concern in many applications. According to industry reports, corrosion is responsible for over $3 billion in damages annually in the U.S. alone. Wires that are exposed to corrosive elements without proper protection can fail quickly. Coated wires create a barrier, significantly reducing corrosion rates. Testing indicates that coating effectiveness can reduce corrosion by as much as 90% under certain conditions.

However, not all coatings are created equal. Some coatings may not adhere well or can wear off over time. It is essential to choose a coating that matches the specific environmental challenges. This choice can mitigate risks effectively. Understanding these factors is crucial for making informed decisions in wire applications. Proper evaluation ensures that the benefits of wire coatings are fully realized.

When it comes to electrical installations, safety is paramount.

The electrical insulation properties of Eaw wire coatings significantly enhance safety. These coatings create a barrier that prevents accidental contact between conductive materials.

According to a report by the International Electrotechnical Commission, improper insulation causes around 30% of electrical fires. High-quality coatings can reduce this risk substantially.

In addition to fire prevention, Eaw wire coatings provide excellent resistance against moisture and chemicals. This guarantees not only longevity but also reliability in various environments.

A study published by the National Electrical Manufacturers Association found that the right insulation can increase a wire's lifespan by up to 50%. This translates into fewer replacements and lower costs in the long run.

Tips:

Ensure to regularly inspect your wiring for any signs of wear or damage. Even the best coatings can degrade over time. If unsure about the condition of your insulation, consider consulting with a professional. Regular maintenance is often overlooked, yet it’s crucial for maintaining safety standards. Protecting your installations today can prevent significant issues down the road.

Eaw wire coating offers substantial cost-effectiveness in production processes. By reducing waste, it enhances operational efficiency. This leads to lower expenses in raw materials. Investing in Eaw wire coating can yield long-term savings. It may seem like an extra cost initially, but the returns are significant.

Tips: Consider analyzing current production costs. Look for areas where coatings can minimize material waste. Sometimes, it’s easy to overlook potential savings in smaller processes.

Moreover, Eaw coatings can extend the lifespan of wires and cables. This results in fewer replacements and less downtime. As a result, the overall cost of ownership decreases. However, some might hesitate to transition due to initial investment fears. It’s essential to weigh these concerns against long-term benefits.

Tips: Gather feedback from teams using the coating. Learn from their experiences to refine your approach. Continuous improvement can lead to better resource management.

This chart illustrates the top five benefits of Eaw wire coating in production processes. Each benefit is represented by a percentage, showcasing its significance in enhancing production efficiency and product quality.